Learn how to prepare a SOP for settle plates of environmental monitoring by for microbial air sampling and ensuring compliance standard guideline.

1. PURPOSE

To describes the procedure for monitoring airborne microbial contamination using the Settle Plate Method.

2. SCOPE

This SOP is applicable to the environmental monitoring of controlled areas, including production and aseptic areas.

3. RESPONSIBILITIES

3.1 Microbiologist is Responsible for executing the procedure and documenting results.

3.2 Quality Control (QC) Manager is responsible to reviews and approves results to ensure compliance with acceptance criteria.

3.3 Production Personnel is responsible to ensure environmental conditions are maintained according to established protocols.

4. ACCOUNTABILITY

Head of the Quality Control Department

5. ASSOCIATED DOCUMENTS / REFERENCES

5.1 SOP for media preparation.

5.2 SOP for environmental monitoring protocols.

5.3 EU GMP Annex 1, WHO TRS 1044 – Annex 2

6. PRECAUTIONS

6.1 Avoid unnecessary movement in the monitored area during the exposure period.

6.2 Ensure personnel wear appropriate protective clothing to minimize contamination.

6.3 Handle agar plates carefully to prevent contamination during handling and transportation.

6.4 Discard used plates as per biological waste disposal guidelines.

7. PROCEDURE

7.1 Materials and Equipment

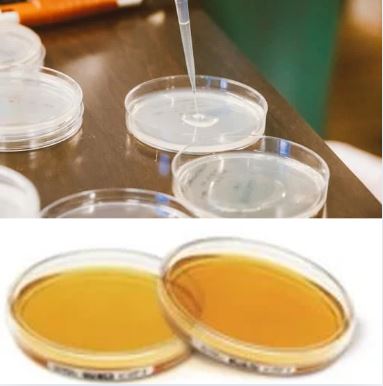

7.1.1 SCDA (Soybean Casein Digest Agar) for bacterial count.

7.1.2 PDA (Potato Dextrose Agar) for fungal count.

7.1.3 Settle plates (90 mm Petri dishes).

7.1.4 Markers or labels.

7.1.5 Incubator (set to 30-35°C for SCDA, 20-25°C for PDA).

7.1.6 Protective gear (gloves, gown, mask).

7.2 Preparation of Media

7.2.1 SCDA (Soybean Casein Digest Agar)

7.2.1.1 Typically, 40g/L of powder with distilled water. Adjust the media volume as per ratio 40g/L. (40 g of SCDA media powder in 1000 ml distilled water).

7.2.1.2 Weigh the desired amount of media.

7.2.1.3 Add the weighed powder to the appropriate volume of distilled water.

7.2.1.4 Stir the solution on a hot plate or magnetic stirrer until completely dissolved.

7.2.1.5 Check the pH using a calibrated pH meter and adjust if necessary to the range specified by the manufacturer:

7.2.1.6 Adjust the pH 7.3 ± 0.2. If needed use dilute HCl or NaOH for pH adjustments.

7.2.1.7 Pour the prepared media into glass bottles or media containers, leaving space for expansion during autoclaving.

7.2.1.8 Sterilize the media at 121°C and 15 psi pressure for 15–20 minutes.

7.2.1.9 Allow the autoclaved media to cool to about 45–50°C to prevent condensation on the petri dishes.

7.2.1.10 Transfer the cooled media into a sterile laminar airflow hood.

7.2.1.11 Pour approximately 15–20 mL of media into each sterile petri dish to ensure an even layer.

7.2.1.12 Check for any contamination or imperfections

7.2.1.13 Label each plate with the media type, preparation date, and expiration date.

7.2.2 PDA (Potato Dextrose Agar)

7.2.2.1 Typically, 39g/L of powder with distilled water. Adjust the media volume as per ratio 39g/L. (39 g of PDA media powder in 1000 ml distilled water).

7.2.2.2 Weigh the desired amount of media.

7.2.2.3 Add the weighed powder to the appropriate volume of distilled water.

7.2.2.4 Stir the solution on a hot plate or magnetic stirrer until completely dissolved.

7.2.2.5 Check the pH using a calibrated pH meter and adjust if necessary to the range specified by the manufacturer:

7.2.2.6 Adjust the pH 5.6 ± 0.2. If needed use dilute HCl or NaOH for pH adjustments.

7.2.2.7 Pour the prepared media into glass bottles or media containers, leaving space for expansion during autoclaving.

7.2.2.8 Sterilize the media at 121°C and 15 psi pressure for 15–20 minutes.

7.2.2.9 Allow the autoclaved media to cool to about 45–50°C to prevent condensation on the petri dishes.

7.2.2.10 Transfer the cooled media into a sterile laminar airflow hood.

7.2.2.11 Pour approximately 15–20 mL of media into each sterile petri dish to ensure an even layer.

7.2.2.12 Check for any contamination or imperfections

7.2.2.13 Label each plate with the media type, preparation date, and expiration date.

7.3 Exposure of Settle Plates

7.3.1 Place the settle plates at designated monitoring locations. Position plates around 1 meter above the floor, near critical areas, equipment, or high-traffic zones.

7.3.2 Expose the plates for the required period, typically 1 to 4 hours, depending on standard practices or regulatory guidelines.

7.4 Incubation

7.4.1 After exposure, cover the plates and transfer them to the incubator:

7.4.2 SCDA plates: Incubate at 30-35°C for 48-72 hours for bacterial growth.

7.4.3 PDA plates: Incubate at 20-25°C for 5-7 days for fungal growth.

7.5 Observation and Recording

7.5.1 After incubation, examine the plates for microbial growth. Record the colony-forming units (CFUs) observed on each plate.

7.6 Results and Limits

7.6.1 Compare the results with acceptance criteria and limits for the area.

7.6.2 Notify Quality Assurance and initiate an investigation if the limits are exceeded.

7.6.3 Record all observations, including CFUs per plate, media type, exposure duration, and any deviations.

7.6.4 Log results in an Environmental Monitoring Log book.

7.6.5 Acceptance Criteria Table for environmental monitoring using the settle plate method.

Table: Limits for Microbial count:

| Cleanroom Grade/Area | Settle Plate Exposure Time | Settle Plates (90 mm diameter) (CFU/plate) | Alert Level | Action Level |

| Grade A (Critical Areas, e.g., aseptic filling) | 4 hours | No growth | <1 | <1 |

| Grade B (Background areas for aseptic operations) | 4 hours | ≤5 | 3 | ≤5 |

| Grade C (Less critical areas, non-aseptic preparation) | 4 hours | ≤50 | 30 | ≤50 |

| Grade D (General cleanroom areas) | 4 hours | ≤100 | 75 | ≤100 |

Note: This table typically follows cleanroom classifications (Grade A-D) in pharmaceutical manufacturing, as specified by regulatory standards like for pharmaceutical environments; refer to EU GMP Annex 1, WHO TRS 1044 – Annex 2.

8. DEFINITIONS AND ABBREVIATIONS

8.1 Environmental Monitoring (EM): The process of measuring physical and microbiological parameters of the environment to ensure compliance.

8.2 CFU (Colony-Forming Units): Values refer to the total count of viable microorganisms found on each plate.

8.3 Alert Level: Indicates the need for closer observation; an alert does not necessarily mean immediate action but signals potential drift toward contamination.

8.4 Action Level: Indicates a breach of acceptable limits, requiring an investigation, root cause analysis, and corrective actions to address contamination.

8.5 QC: Quality Control

8.6 SCDA: Soybean Casein Digest Agar

8.7 PDA: Potato Dextrose Agar

8.8 ISO: International Organization for Standardization

8.9 SOP: Standard Operating Procedure

8.10 EU: European Union

8.11 USP: United States Pharmacopoeia

8.12 GMP: Good Manufacturing Practice

8.13 HCl: Hydrochloric acid

8.14 NaOH: Sodium Hydroxide

9. ANNEXES

9.1 Annex-1: Log Book for Settle Plate Method

10. REVISION HISTORY

| Version | Date | Description of Change | Reviewed By | Approved By |

| 1.0 |

Read Also:

- SOP for Maintenance of Stock Cultures in Microbiology

- SOP for Growth Promotion Test of Media

- SOP for Qualification of Autoclave

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.