Learn how to write a standard cleaning procedure of production area in pharmaceutical industry.

1. PURPOSE

To describe a proper house-keeping & cleanliness at the production areas for minimizing contamination

2. SCOPE

This procedure is applicable for cleaning of all production areas in this pharmaceutical.

3. ASSOCIATED DOCUMENTS

Nil

4. PRECAUTIONS

4.1 Wear apron and mask appropriately before starting of cleaning.

4.2 Always use freshly prepared detergent and disinfectant solution.

4.3 Check the purified water supply before starting of cleaning.

5. RESPONSIBILITIES

5.1 Operator, helper and cleaners are responsible for cleaning of production are

5.2 Production Executive is responsible for checking and ensuring the cleaning of all areas in the Production Department.

5.3 Production Manager is responsible for implementation and cross checking and ensuring thecleaning of all areas in the Production Department.

6. ACCOUNTABILITY

Head of the Quality Assurance Department

7. PROCEDURE

7.1 Clip a clean duster with a mopping stick.

7.2 Soak mopping edge with disinfectant solution.

7.3 Mop floor from furthest comer to opening side.

7.4 Clean specific areas at specific times of period according to the chart below:

| Areas/ Objects | Mode of cleaning | Frequency |

| Floor (Machine Room) | By vacuum Cleaner, Wet mop | At each Product changeover / When required |

| Walls (Machine Room) | By dry & wet Cloth | At each Product changeover / When required |

| Doors and Windows (Machine Room) | By wet cloth | At each Product changeover / When required |

| Ceiling & Light sheds (Machine Room) | By wet cloth | At each Product changeover / When required |

| Floors (Dispensed material staging room, WIP store) | By vacuum cleaner and wet mop. | Twice per day |

| Floors (All change room, corridors & stair, Tools room, IPQC room, Office room, Secondary Packaging area) | By vacuum cleaner, By wet cloth & 1% disinfectant | Twice per day/When required |

| Floor (Washing bay) | By wet mop & 1% disinfectant | Three times per day/ When required |

| Walls (All Change rooms, Tools room, IPQC room, Office room, Secondary packaging area, Corridor, Dispensed RM staging room, WIP store & Washing bay) | By dry cloth duster | Once per week |

| Ceilings & Light sheds (All Change rooms, Secondary packaging area, Corridor, WIP store, Tools room, Dispensed RM staging room, IPQC room, Washing bay, Office room) | By dry cloth duster | Once per week |

| Racks (WIP store & Tools Room) | By wet cloth | Twice per week |

| Doors & Windows including glass (All Change rooms, Stair room, Secondary packaging area, corridor, WIP store, Tools room, Dispensed RM staging room, IPQC room, Washing bay, Office room) | By wet cloth duster and glass cleaner | Once per day |

| Table, Chair, Working bench, dress locker & step over bench | By wet / dry cloth duster | Once per day |

| Waste bins | By cleaning agent | At each Product changeover / Once daily / When required |

| Return air duct filter | By purified water & compressed air | At each Product changeover |

| Trolleys | By wet cloth | After each use / When required |

7.5 Use of disinfectant solution: 1st week- Savlon, 2nd week – Dettol, 3rd week Savlon, 4th week- Dettol and so on.

7.6 Keep the record in the Room Cleaning Log Book & Production Area Cleaning Log Book and fill up the Cleaning Check Sheet,

where necessary.

Read Also: SOP for Cleaning of Sampling Tools

SOP for Cleaning of QC Laboratory

8. ABBREVIATIONS

8.1 SOP: Standard Operating Procedure

8.2 PRO: Production

9. APPENDICES

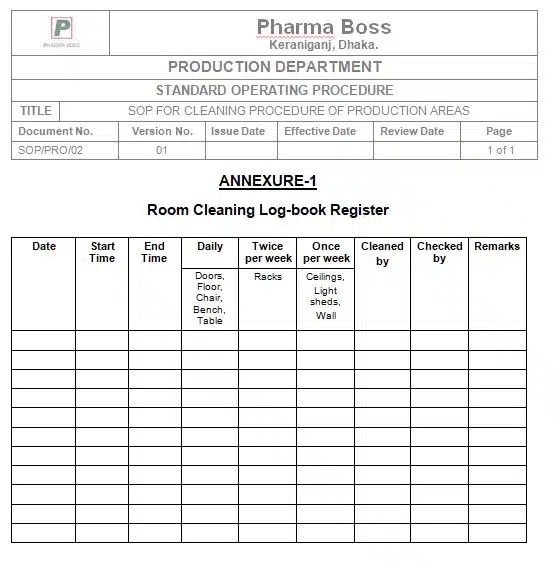

9.1 Annexure-1: Room Cleaning Log Book Register.

9.2 Annexure-2: Production Area Cleaning Log Book Register

SOP For Cleaning Procedure of Production Area Annexure-1: Room Cleaning Log Book Register.

SOP For Cleaning Procedure of Production Area Annexure-2: Production Area Cleaning Log Book Register.

ANNEXURE-2 Production Area Cleaning Log-book Register

| Date | Start Time | End Time | Daily | Twice per week | Once per week | Cleaned by | Checked by | Remarks |

| Doors, Floor, Chair, Bench, Table | Racks | Ceilings, Light sheds, Wall | ||||||

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.