Learn how to write a SOP for Qualification of Working Standard in the Quality Control Laboratory at Pharmaceuticals.

Table of Contents

1.0 PURPOSE

To describe the procedure for qualification and assigning expiry dates of working standards.

2.0 SCOPE

This SOP is applicable to all analytical working standards used and will be standardized in the Quality Control Department.

3.0 RESPONSIBILITIES

3.1 Executive, QC is responsible for receiving reference standards, preparing, labeling, and expiry dating of working standards.

3.2 Sr. Executive/Asst. Manager, QC is responsible for checking reference standards, preparing, labeling, and expiry dating of working standards.

4.0 ACCOUNTABILITY

Head of Quality Assurance

5.0 ASSOCIATED DOCUMENTS

Nil

6.0 DEFINITIONS

6.1 Reference Standard: Chemical substance whose potencies are known and used as a reference sample in UV, IR, and chromatographic procedures.

6.2 Working standard: A chemical substance that is standardized against a reference standard and is used as control material during analysis.

6.3 Expiry dates: The dates placed on the label of the container of a material that designates the dates through which the material is expected to remain within BP/ USP specification

7.0 PRECAUTIONS

Immediately recap the container having working standard after its opening.

8.0 PROCEDURE

8.1 Qualification

8.1.1 Received analytical reference standard from approved source.

8.1.2 Record the date on each container on receipt.

8.1.3 Record the name of the materials, reference/batch no., strength, Date of receipt, and quantity.

Origin or any other reference in the register book.

8.1.4 Select a batch of active raw materials in order to prepare the working standard considering the following:

8.1.4.1 Quality Assurance passed material.

8.1.4.2 Procured from approved vendor.

8.1.4.3 Manufacturer’s Certificate.

8.1.4.4 Expiry of the material declared by the manufacturer.

8.1.4.5 Analytical results obtained during analysis of the material.

8.1.4.6 Potency of the material as near as reference standard.

8.1.4.7 Impurity complies with pharmacopoeia specification.

8.1.4.8 Collect data or test procedure from the supplier if the material is not included in the pharmacopeia.

8.1.5 Determine the strength of the material by standardizing with the analytical reference standard following the approved method.

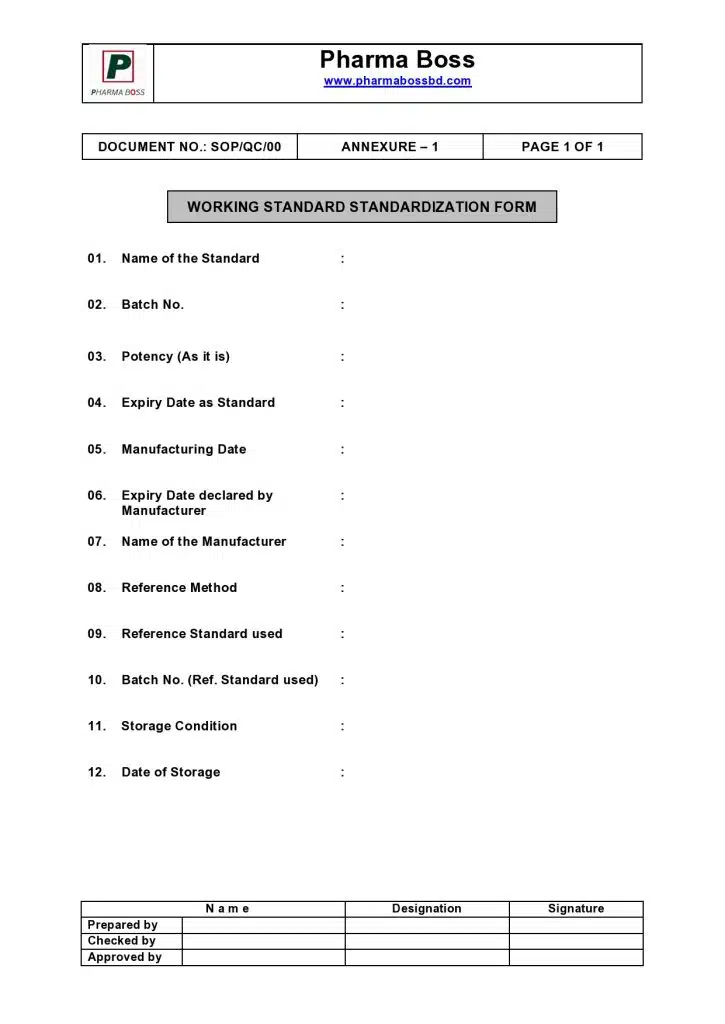

8.1.6 Fill up the working standard standardization form (Annexure – 1)

8.1.7 Archive all standardization documents for 5 years after the use of the working standard.

8.1.8 Label the working standard with the following information:

- Name of the standard

- Date of preparation

- Strength

- Expiry

- Batch No.

- Prepared by

- Maintain a list of analytical working standards mentioning the location.

8.2 Expiry Dating

8.2.1 Give the one-year expiry date of the working standard.

8.2.2 Consider the following while giving such expiry dates

– Manufacturer’s Certificate

– Expiry of the material declared by the manufacturer.

– Analytical results obtained during analysis of the material.

– Potency of the material as near as the reference standard.

– Impurities comply with pharmacopoeia specification.

8.2.3 Extend the expiry date of the working standard for another year if the test result complies with the previous result at the end of one year and must comply with BP/ USP/ In-house specification.

Also Read: SOP for Batch Numbering System of Raw and Packaging Materials.

9.0 ABBREVIATION

9.1 QA – Quality Assurance

9.2 QC – Quality Control

9.3 SOP– Standard Operating Procedure

9.4 BP- British Pharmacopoeia

9.5 USP- United State Pharmacopoeia

9.6 UV- Ultraviolet

9.7 IR- Infrared

10. ANNEXURES

10.1. Annexure-1: Working Standard Standardization Form.

Frequently Asked Questions (FAQ)

What is a Working Standard?

A Working Standard is often a subset of a Reference Standard. While both are well-characterized materials, a Working Standard is typically used within a specific laboratory or company for daily comparisons, while a Reference Standard serves as a broader industry-wide benchmark.

What is a Reference Standard?

A Reference Standard is a well-defined substance with established properties, used as a benchmark for evaluating the quality, accuracy, and performance of instruments, assays, or methods in various fields like pharmaceuticals, chemistry, and metrology.

How is a Working Standard different from a Reference Standard?

A Working Standard is a sample, substance, or material that is precisely characterized and used as a point of comparison during analytical processes or quality control procedures. It assures accurate measurements and consistent results.

What is the importance of Working Standards and Reference Standards?

Standards and Reference Standards are crucial for maintaining consistency and accuracy in measurements, analyses, and quality control. They ensure that instruments are calibrated correctly and that test results can be trusted across different laboratories and over time.

How are Working Standards and Reference Standards established?

Working Standards are often derived from a Reference Standard through dilution or modification to suit specific applications. Reference Standards are established through rigorous characterization, often by reputable organizations, using techniques like spectroscopy, chromatography, or mass spectrometry to define their properties precisely.

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.