Learn how to write SOP for Receiving of Raw and Packaging Materials in the warehouse.

Table of Contents

1.0 PURPOSE

To set up the procedure for receiving and inspecting incoming raw and primary packaging materials in the warehouse.

2.0 SCOPE

This SOP is applicable for all incoming raw and primary packaging materials for pharmaceuticals in the warehouse.

3.0 RELATED DOCUMENTS

3.1 SOP for the transfer of raw and packaging materials to quarantine storage.

3.2 SOP for handling damaged containers of raw materials.

3.3 SOP for the reception and storage of flammable solvents.

3.4 SOP for batch numbering of raw and packaging materials.

4.0 RESPONSIBILITIES

4.1 Executive/Officer Warehouse is responsible for receiving and checking documents and maintaining the record.

4.2 The warehouse supervisor is responsible for inspecting the truck or van before and after unloading, putting it on the rack, marshaling, damage checking, weighing, quarantining the materials, and raising GRN.

4.3 The security person is responsible for checking the materials as per the challan or invoice and maintaining the log book.

5.0 ACCOUNTABILITY

Head of Department

6.0 PRECAUTIONS

Handle fragile containers with care and separate them from good containers.

People Read Also: SOP for Dress Changing Procedure of Personnel in Warehouse

People Read Also: SOP for Labeling of Raw and Packaging Materials

7.0 PROCEDURE

7.1 Allow the truck to park at the ‘Unloading Bay’ of the ‘Raw Material Warehouse and inspect the truck’.

7.2 Check that all necessary documents (Challan, invoice etc.) are available.

7.3 Compare the items with the purchase order. Challan & Invoice.

7.4 Inform the commercial department if any abnormality or discrepancy is found on any document.

7.5 Unloading

7.5.1 Arrange to unload the material with proper care.

7.5.2 When unloading the materials, it is necessary to present the security person.

7.5.3 Clean the containers/bags with a rag and use a vacuum cleaner if necessary.

7.5.4 Put the containers/bags on the shelf according to the direction ( ) indicated on the label.

7.5.5 Follow the safety measures during unloading the solvent containers (e.g., flammable or organic solvents, etc.)

7.6 Marshaling, checking & Weighing

7.6.1 Sort out the damaged (broken seal, tapped, breakage, leakage, etc.) containers/bags/reels by Visual inspection while putting them on the rack. Repack or segregate the damaged containers according to related.

7.6.2 Count the number of containers and compare the quantity with the Challan.

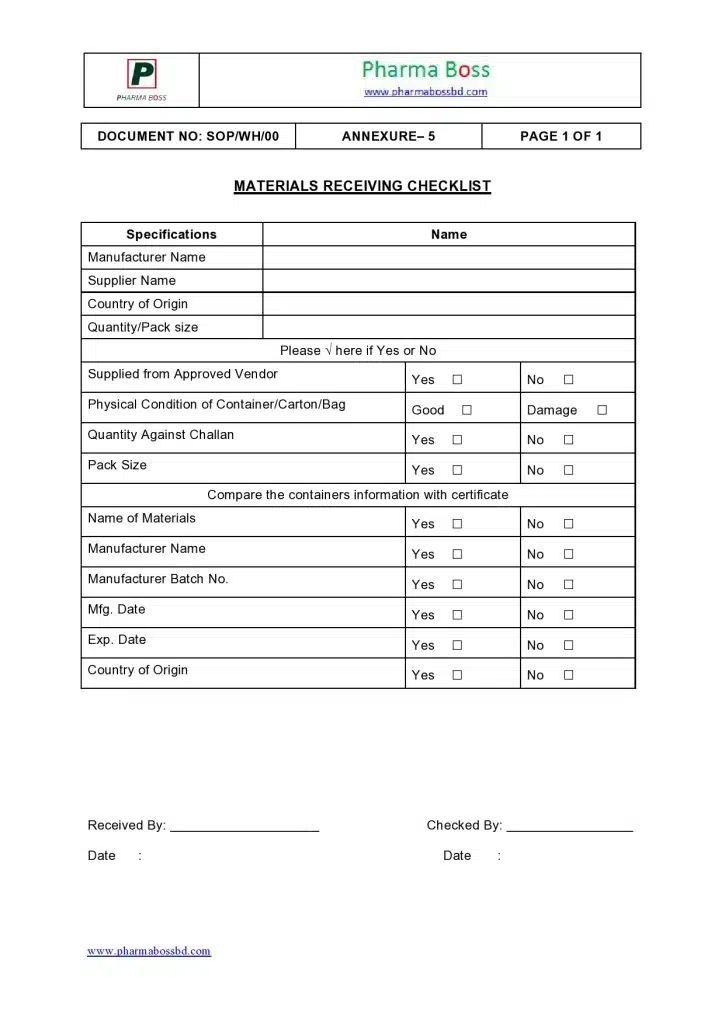

7.6.3 Check the container visually for appropriate labeling Name of material, Batch no. Expiry date, supplier/ manufacturer name (Annexure 5).

7.6.4 Weigh the materials and verify the declared gross weight. Determine the net weight by subtracting the declared tare weight from the gross weight and recording it in the raw materials/foil receiving register.

7.6.5 Segregate the containers following the supplier’s batch number.

7.6.6 Allocate batch number. for a supplier of each batch of material following the related SOP.

7.6.7 Transfer the materials to the quarantine area with the proper status label, following the related SOP.

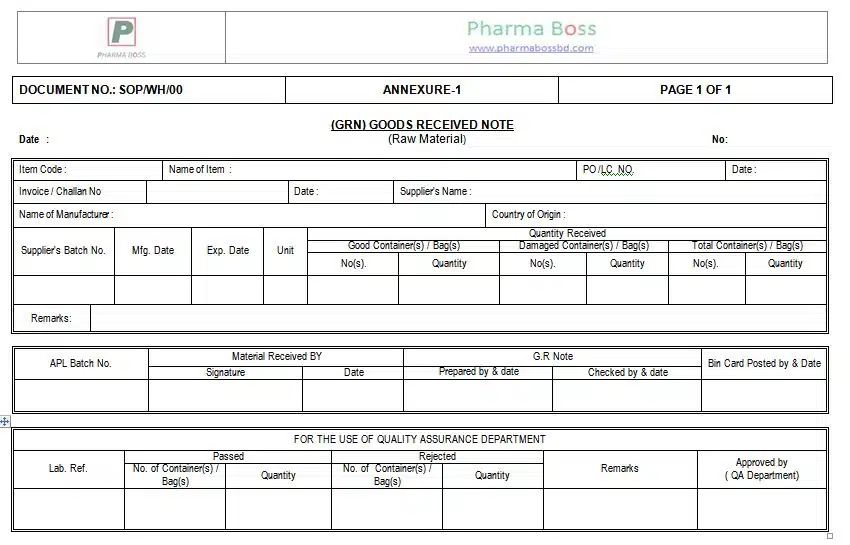

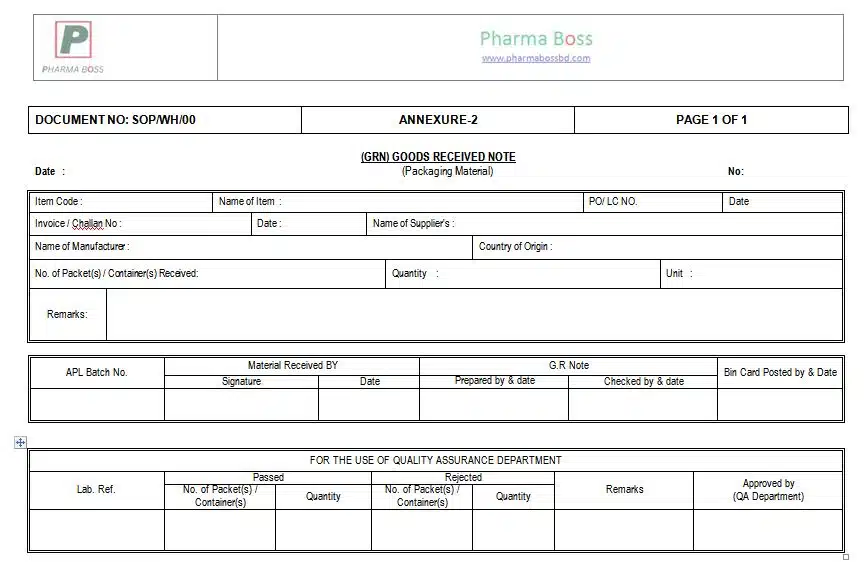

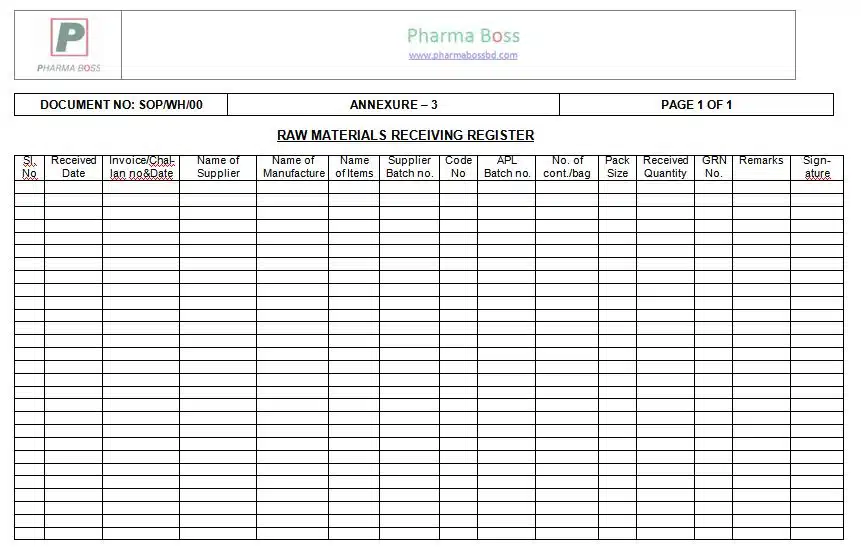

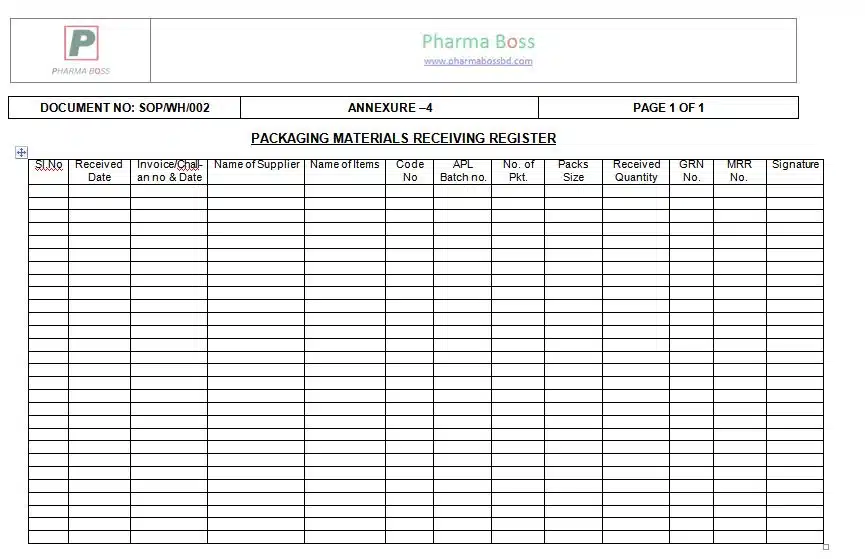

7.6.8 Fill up the GRN (Annexure-1 / or Annexure 2) Register (Annexure 3-Annexure-4) and send it to the Quality Assurance Department.

7.6.9 After quality control, release or reject the materials and transfer them to the passed or rejected area.

8.0 ABBREVIATIONS

8.1 SOP: Standard Operating Procedure

8.2 GRN: Goods Received Note

9.0 ANNEXURES

9.1 Annexure 1: GRN (Goods Received Note) for Raw Material.

9.2 Annexure 2: GRN (Goods Received Note) for Packaging Material.

9.3 Annexure 3: Raw Material Receiving Register Format.

9.4 Annexure 4: Packaging Material Receiving Register Format.

9.5 Annexure 5: Materials Receiving Checklist.

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.

vibrometer

Discover the Power of the Vibrometer: Balanset-1A Portable Balancer & Vibration Analyzer

In today’s fast-paced industrial world, maintaining the efficiency and longevity of machinery is paramount. One of the critical tools in ensuring that machines run smoothly is the vibrometer. This innovative device plays a significant role in identifying imbalances and diagnosing mechanical faults. Introducing the Balanset-1A, a portable balancer and vibration analyzer that empowers you to harness the full potential of vibrometry for dynamic balancing across a wide range of applications.

Why Choose the Balanset-1A Vibrometer?

The Balanset-1A stands out in functionality and versatility, making it a top choice for professionals in various industries. It’s equipped with advanced features that provide precise measurements for effective rotor balancing. With the Balanset-1A, you can confidently work with crushers, fans, mulchers, augers, centrifuges, turbines, and many other rotors, ensuring optimal performance and reliability.

Your Complete Vibration Analysis Solution

The Balanset-1A vibrometer is not just a balancing tool; it offers a comprehensive solution for vibration analysis. The device includes two vibration channels, enabling detailed assessments of vibrational impact in two planes. This dual capability is essential for accurately identifying and mitigating potential issues before they lead to more significant complications.

Advanced Features for Enhanced Performance

With the Balanset-1A, you’ll find a wealth of features designed to streamline the balancing and analysis process:

Vibrometer Mode: Engage with multiple analytical capabilities, such as measuring rotational speed (RPM), phase determination, FFT spectrum analysis, and more.

Balancing Modes: Choose between single-plane and two-plane balancing to cater to your specific rotor requirements, effectively reducing vibrations.

Measurement Logging: Store critical measurement data for future reference and analysis, enhancing your operational efficiency.

Visualize Your Balancing Efforts

The Balanset-1A also features dynamic visual tools. With its polar graph capability, you can accurately visualize the imbalance, making it simple to determine where corrective weights are needed. This visualization simplifies the balancing process, thereby allowing for quick adjustments that lead to substantial improvements in machine performance.

Precision and Accuracy at Your Fingertips

Precision is non-negotiable in vibration analysis and balancing. The Balanset-1A ensures accuracy through its detailed measurement capabilities. It can track vibration levels, phase shifts, and rotational speeds with minimal error margins, ensuring that you receive reliable data to inform your decisions.

Endless Possibilities in Vibration Analysis

Whether you’re interested in monitoring overall vibration levels, analyzing specific frequency components, or generating detailed reports, the Balanset-1A has got you covered. Its spectrum charts provide a graphical representation of frequency data, helping users understand intricate aspects of their machinery’s performance. The archival feature allows you to store historical data, making trend analysis and performance evaluations more accessible than ever.

Global Compatibility and User-Friendly Interface

Knowing that industries operate worldwide, the Balanset-1A supports both Imperial and Metric systems, ensuring that it is a truly global solution. Furthermore, the user-friendly interface and included software make it easy to connect the device to a PC, allowing for seamless data transfers and analysis. This accessibility means that whether you’re a seasoned professional or just starting, you can quickly become proficient with the device.

Investing in Quality and Reliability

When you invest in the Balanset-1A vibrometer, you’re investing in quality and reliability. This portable balancer is built to endure the rigors of daily use in various industrial settings. Weighing just 4 kg, it is also designed for easy transport, allowing you to take it wherever it’s needed. Additionally, the product comes with various components to suit your specific requirements, ensuring you have everything you need for effective vibration analysis and balancing right at your fingertips.

Join the Community of Optimizers

Becoming a part of the Balanset community means joining a world of optimization and efficiency. By utilizing the capabilities of the Balanset-1A vibrometer, you contribute to reducing maintenance costs, extending equipment lifespan, and improving safety standards in your workplace. Plus, by subscribing to our plans, you gain access to exclusive discounts and membership benefits, amplifying your purchasing power.

Conclusion

In conclusion, the Balanset-1A is a revolutionary vibrometer that transforms how industries approach balancing and vibration analysis. With its advanced features, precision accuracy, and user-friendly interface, this portable balancer is the perfect companion for any professional involved in machinery maintenance. Don’t just keep your machines running—optimize their performance and extend their service life with the Balanset-1A. Elevate your industrial operations today!

vibration analyzer

Vibration Analyzer: Balanset-1A Overview

The Balanset-1A is a cutting-edge portable vibration analyzer and balancer designed specifically for dynamic balancing of various rotor types. This device is essential for industries managing equipment such as crushers, fans, mulchers, augers on combines, shafts, centrifuges, turbines, and many more. The advanced features of the Balanset-1A make it an indispensable tool in maintaining operational efficiency and extending the lifespan of machinery.

Equipped with dual-channel technology, the Balanset-1A can perform dynamic balancing in two planes, thus enhancing its versatility. By utilizing this advanced vibration analyzer, users can achieve precise balancing and detailed analysis across a wide range of applications. This functionality is not only user-friendly but also efficient, allowing maintenance teams to address vibration issues promptly and effectively.

Key Features and Functionalities

The Balanset-1A is engineered to deliver a comprehensive suite of functionalities. Key features encompass:

Vibrometer Mode: This mode enables the measurement of rotational speeds (RPM), phase angles of vibration signals, fundamental frequency components, and overall vibration levels.

Balancing Mode: The device supports both single and two-plane balancing, allowing users to reduce vibrations effectively. A polar graph visualization aids in accurately placing corrective weights.

Tolerance Calculator: Complying with ISO 1940 standards, this feature computes acceptable balancing tolerances essential for ensuring safety and operational efficiency.

Data Management: The Balanset-1A allows users to save measurement data, generate detailed reports, and restore previous sessions for continuity and ease of use.

FFT Spectrum Analysis: This capability offers a detailed analysis of frequency spectrums, enabling technicians to understand better the specific vibration patterns affecting their equipment.

Additionally, the analyzer provides extensive charting options, including overall vibration, harmonic frequencies, and spectrum charts, allowing for an in-depth review of equipment performance and conditions.

Specifications

The Balanset-1A operates within a robust range of specifications that cater to both Imperial and Metric systems, ensuring compatibility worldwide. The device features:

Two vibration sensors and one optical sensor for accurate RPM measurements.

A range of rotational speed measurement capability from 250 to 90,000 RPM.

RMS vibration velocity measurement capabilities between 0 and 80 mm/s.

Frequency ranges from 5 Hz to 550 Hz, accommodating various operational requirements.

Power requirements of 140-220 VAC, 50 Hz, and lightweight construction at just 4 KG.

Enhanced User Experience

Increased user experience is a hallmark of the Balanset-1A. The device’s intuitive interface allows users to navigate through its extensive features with ease, making it suitable for professionals and beginners alike. The system’s capability to store past measurement data means that technicians can revisit and analyze previous sessions, ensuring a streamlined workflow in operations.

To support global industries, the Balanset-1A can be employed in both serial production balancing scenarios and standalone analyses. This flexibility ensures that businesses can rely on a single tool for varied operational needs. Furthermore, the inclusion of a USB interface allows for easy connection to PCs for software updates and data management.

Applications and Benefits

The applications of the Balanset-1A as a vibration analyzer are vast. Industries, including manufacturing, agriculture, and energy, benefit significantly from employing this device. By ensuring dynamic balancing and monitoring vibrations, businesses can:

Enhance machinery longevity by reducing wear and tear manifested through vibrations.

Prevent unexpected equipment failures, which can incur significant downtime costs.

Improve operational efficiency, leading to better productivity and output.

Minimize maintenance costs through proactive vibrational analysis and balancing.

By investing in the Balanset-1A, companies ensure an operational edge, safeguarding their equipment and ultimately improving their bottom line.

Conclusion

In conclusion, the Balanset-1A is an all-encompassing vibration analyzer and balancer that stands out in today’s competitive operational landscape. Its combination of advanced features, user-friendly interface, and versatile applications positions it as an essential tool across numerous industries. Investing in the Balanset-1A empowers organizations to mitigate operational risks and enhance the performance of machinery significantly. With a price point of €1,751.00, this portable device offers exceptional value for effective rotor balancing and vibration analysis.

For more information about the Balanset-1A and to purchase, interested buyers are encouraged to visit our site and explore the various options available to optimize their machinery’s performance.

Watch YouTube Short

body

font-family: Arial, sans-serif;

line-height: 1.6;

h1

font-size: 24px;

font-weight: bold;

margin-bottom: 20px;

p

font-size: 16px;

margin-bottom: 15px;

ul

list-style-type: disc;

margin-bottom: 15px;

Balancing tools for industrial repair and maintenance applications

Introducing the Balanset-1A rotor balancing device, designed to streamline the maintenance processes in industrial settings. Packed with essential components, this tool ensures precision and efficiency in balancing rotors for optimal performance.

Vibration transducers – 2 pieces

Phase angle sensor (laser tachometer) – 1 piece

Measurement block (Balanset device) – 1 piece

Magnetic stand – 1 piece

Electronic scales – 1 piece

Transportation case – 1 piece

Software on a flash drive – 1 piece

With a price of 1751 euros, the Balanset-1A offers a comprehensive solution for rotor balancing, making it a valuable asset for industrial repair and maintenance tasks.

[b]Contact Information:[/b]

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Machinio

Balanset-1A OEM on eBay