Learn how to write standard procedure for sampling method of packaging materials in the pharmaceutical industry.

1. PURPOSE

The purpose of this procedure is to describe sampling method of packaging materials for ensuring the identity and quality of packaging materials by subsequent testing.

2. SCOPE

This procedure is applicable for sampling method of packaging materials in warehouse of this pharmaceutical.

3. ASSOCIATED DOCUMENTS

Nil

4. PRECAUTIONS

Nil

5. RESPONSIBILITIES

Executive, Quality Control or sampler is responsible for carrying out the sampling procedure.

6. ACCOUNTABILITY

Head of the Quality Assurance Department

7. PROCEDURE

7.1 Receive” Goods Received Note” (GRN)

7.2 Entry your company batch No., Name of packaging material, Lab control no. etc. in a register.

7.3 Select number of packet / reel as per sampling plan.

7.4 Label the sampling container properly.

7.5 Check the physical condition of containers / bags or reel.

7.6 Open the container or box or reel and check the physical condition of the packaging material such as uniformity of color and appearance.

7.7 Check the label of the sample container and verify with respective reel or bags or container.

7.8 Follow ‘normal’ sample plan up to 25 batch.

7.8.1 Change ‘normal’ to ‘reduced‘ sample plan if consecutive 25 batches are acceptable.

7.8.2 Change ‘reduced’ to ‘normal’ sample plan if one batch is failed AQL .

7.8.3 Change ‘normal’ to ‘tightened’ when 2 out of 5 or less consecutive batch have been failed to meet AQL.

7.8.4 Change ‘tightened’ to ‘normal’ when 5 consecutive batch are accepted.

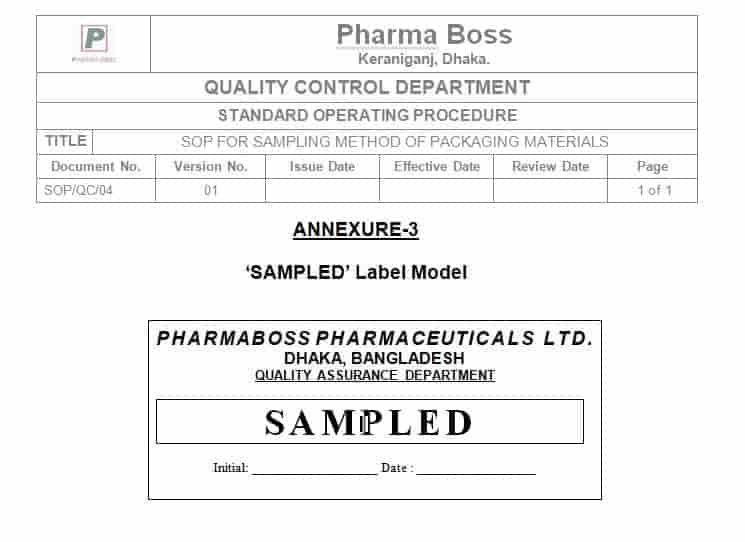

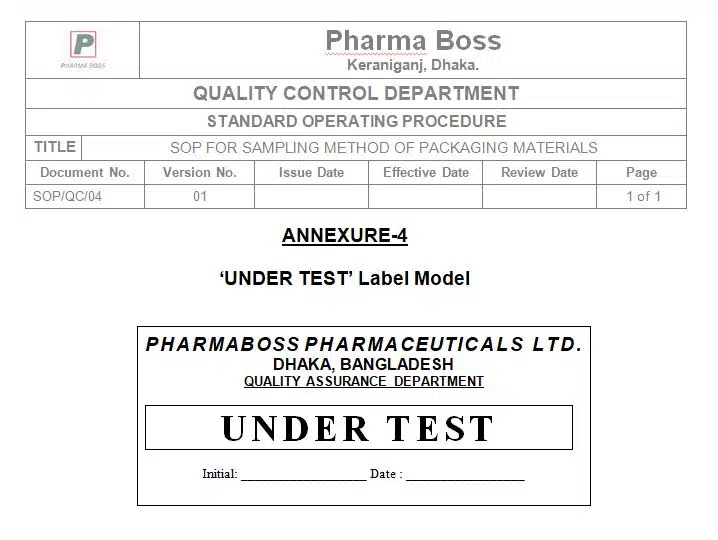

7.9 Prepare and affix the ‘Sampled’ label only sampled reel or bags or container and ‘Under Test’ label each and every reel or bags or container.

7.10 Hand over the samples to Executive / Analyst along with necessary documents.

7.11 Perform the test according to the analytical Specification of packaging Material.

7.12 Keep retention sample from each lot of reel or bags or container with proper labeling at least twice the quantity required to carry out all tests.

7.13 Take sufficient samples to permit repeat test (if necessary).

7.14 Sampling Plan

7.14.1 Determine the number of sampling by √n + 1 for each batch. Where N = total no. of reel or box or container.

7.15 Damaged container

7.15.1 Sample from each damaged reel or box or container.

8. ABBREVIATIONS

8.1 SOP: Standard Operating Procedure

8.2 GRN: Goods Received Note

8.3 AQL: Acceptable Quantity Label

8.4 QC: Quality Control

APPENDICES

9.1 Annexure-1: Packaging Material Sampling Log book

ANNEXURE-1

Packaging Material Sampling Log book

| Date | Name of the Packaging materials | Batch No | GRN No | Container condition | Sample Quantity | Sampled by | Remarks |

9.2 Annexure-2: Packaging Material Register Log book

ANNEXURE-2

Packaging Material Register Log book

| Date | Name of the Packaging materials | Batch No. | GRN No. | Lab Control No | Name of the Manufacturer | Sampled by | Tested by | Quantity | Remarks |

9.3 Annexure-3: ‘SAMPLED’ Label Model

9.4 Annexure-4: ‘UNDER TEST’ Label Model

9.5 Annexure-5: Sampling Plan

ANNEXURE-5

SAMPLING PLAN

| Sample Position | Batch Size (pcs) | Sample Size (pcs) | Acceptable | Rejected |

| Normal | 2 – 8 | 2 | Nil | 1 |

| 9 – 15 | 2 | Nil | 1 | |

| 16 – 25 | 3 | Nil | 1 | |

| 26 – 50 | 5 | Nil | 1 | |

| 51 – 90 | 5 | Nil | 1 | |

| 91 – 150 | 8 | 1 | 2 | |

| 151 – 280 | 13 | 1 | 2 | |

| 281 – 500 | 13 | 1 | 2 | |

| 501 – 1,200 | 20 | 2 | 3 | |

| 1,201 – 3,200 | 32 | 3 | 4 | |

| 3201 – 10000 | 32 | 3 | 4 | |

| 10,001 – 35,000 | 50 | 5 | 6 | |

| 35,001 – 150,000 | 80 | 7 | 8 | |

| 150,001 – 500,000 | 80 | 7 | 8 | |

| 500,000 – Over | 125 | 10 | 11 | |

| Reduced | 2 – 8 | 2 | Nil | 1 |

| 9 – 15 | 2 | Nil | 1 | |

| 16 – 25 | 2 | Nil | 1 | |

| 26 – 50 | 2 | Nil | 1 | |

| 51 – 90 | 2 | Nil | 1 | |

| 91 – 150 | 3 | Nil | 2 | |

| 151 – 280 | 5 | Nil | 2 | |

| 281 – 500 | 5 | Nil | 2 | |

| 501 – 1,200 | 8 | 1 | 3 | |

| 1,201 – 3,200 | 13 | 1 | 4 | |

| 3,201 – 10,000 | 13 | 1 | 4 | |

| 10,001 – 35,000 | 20 | 2 | 5 | |

| 35,001 – 150,000 | 32 | 3 | 6 | |

| 150,001 – 500,000 | 32 | 3 | 6 | |

| 500,000 – Over | 50 | 5 | 8 | |

| Sample Position | Batch Size (pcs) | Sample Size (pcs) | Acceptable | Rejected |

| Tightened | 2 – 8 | 2 | Nil | 1 |

| 9 – 15 | 2 | Nil | 1 | |

| 16 – 25 | 3 | Nil | 1 | |

| 26 – 50 | 5 | Nil | 1 | |

| 51 – 90 | 5 | Nil | 1 | |

| 91 – 150 | 8 | 1 | 2 | |

| 151 – 280 | 13 | 1 | 2 | |

| 281 – 500 | 13 | 1 | 2 | |

| 501 – 1,200 | 20 | 1 | 2 | |

| 1,201 – 3,200 | 32 | 2 | 3 | |

| 3,201 – 10,000 | 32 | 2 | 3 | |

| 10,001 – 35,000 | 50 | 3 | 4 | |

| 35,001 – 150,000 | 80 | 5 | 6 | |

| 150,001 – 500,000 | 80 | 5 | 6 | |

| 500,000 – Over | 125 | 8 | 9 |

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.