Learn how to write a standard procedure for stability testing in pharmaceuticals, including guidelines for sample preparation, storage conditions, and data analysis to ensure product quality and safety.

1. PURPOSE

To describe the procedures for conducting excipient compatibility studies to ensure that excipients used in the formulation of a pharmaceutical product do not interact negatively with the active pharmaceutical ingredient (API) or with each other, potentially affecting the safety, efficacy, or stability of the final product.

2. SCOPE

This SOP applies to all excipient compatibility studies conducted for APIs under development. It covers the selection of excipients, preparation of physical mixtures, testing procedures, data analysis, and documentation requirements.

3. RESPONSIBILITIES

3.1 Research and Development (R&D) Team: Responsible for designing the study protocol, conducting experiments, and analyzing data.

3.2 Quality Control (QC) Team: Responsible for ensuring all tests are conducted according to approved methods and documenting results.

3.3 Regulatory Affairs: Responsible for ensuring compliance with regulatory guidelines and documentation requirements.

3.4 Quality Assurance: Responsible for approving and archiving the documents.

4. ACCOUNTABILITY

Head of the concerned department

5. ASSOCIATED/ REFERENCE DOCUMENTS

5.1 International Council for Harmonization (ICH) Guidelines Q1A (R2) – Stability Testing of New Drug Substances and Products

5.2 United States Pharmacopeia (USP)

5. PRECAUTIONS

Nil

7. PROCEDURE

7.1 Selection of Excipients

7.1.1 Identify excipients commonly used in similar formulations or as recommended by formulation scientists.

7.1.2 Evaluate the excipients’ chemical nature, physical properties, and prior documented compatibility with APIs similar to the one under study.

7.2 Preparation of Physical Mixtures

7.2.1 Accurately weigh API and excipients based on a predefined ratio (e.g., 1:1, 1:5, 1:10) as per the formulation requirements.

7.2.2 Mix the API and excipient using a mortar and pestle or a suitable mixer to ensure homogeneity.

7.2.3 Store the physical mixture in appropriate containers labeled with the mixture details, date, and storage conditions.

7.3 Storage Conditions for Compatibility Testing

7.3.1 Prepare samples for accelerated and long-term stability studies.

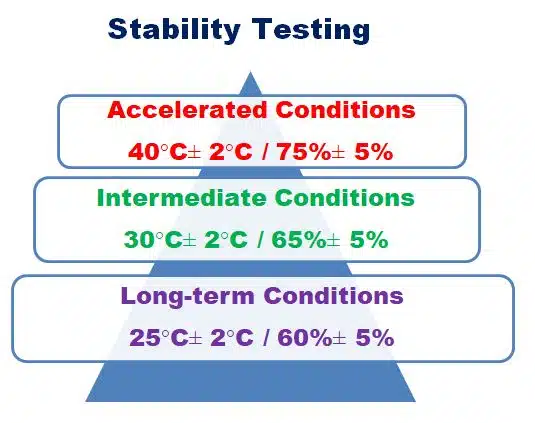

7.3.2 Store samples at various conditions such as:

40°C ± 2°C / 75% RH ± 5% RH (Accelerated conditions)

30°C ± 2°C / 65% RH ± 5% RH (Intermediate conditions)

25°C ± 2°C / 60% RH ± 5% RH (Long-term conditions)

7.3.3 Monitor and document the conditions regularly.

7.4 Analytical Testing

7.4.1 Initial Testing: Conduct initial testing using analytical techniques like DSC, TGA, HPLC, and FTIR to detect any physical or chemical interaction between the API and excipients.

7.4.2 Periodic Testing: At predetermined intervals (e.g., 1 month, 3 months, 6 months, 12 months), perform analytical testing on samples stored under different conditions to assess any changes in the mixture.

7.4.3 Data Analysis: Compare the results with the initial data to identify any significant changes indicating incompatibility (e.g., new peak formation in chromatograms, melting point changes, weight loss).

7.5 Documentation

7.5.1 Record all observations and test results in a laboratory notebook or electronic system.

7.5.2 Maintain a compatibility study report that includes:

Objectives

Methodology

Results and Discussion

Conclusion and Recommendations

7.5.3 Ensure all documents are reviewed and approved by relevant team members.

8. ABBREVIATIONS

8.1 SOP: Standard Operating Procedure

8.2 API: Active Pharmaceutical Ingredient

9. ANNEXURES

Nil

Frequently Asked Questions (FAQs)

What is stability testing in pharmaceuticals, and why is it important?

Stability testing in pharmaceuticals is a process that evaluates how the quality of a drug substance or drug product changes over time under the influence of environmental factors such as temperature, humidity, and light. The main goal is to determine the drug’s shelf life, ensure its safety and efficacy, and establish appropriate storage conditions. This testing is crucial for regulatory compliance and to guarantee that the medication remains effective and safe throughout its intended shelf life.

What are the different types of stability testing?

There are several types of stability testing, including:

Real-Time Stability Testing: Conducted under normal storage conditions to assess how the product performs in its intended environment over its shelf life.

Accelerated Stability Testing: Involves storing the product under increased stress conditions (e.g., higher temperatures) to speed up the aging process and predict its long-term stability.

Intermediate Stability Testing: Used to bridge between real-time and accelerated testing, often conducted at conditions that are intermediate between normal and accelerated conditions.

Long-Term Stability Testing: Evaluates the product over extended periods under normal storage conditions to confirm its shelf life.

How is stability testing conducted and what factors are evaluated?

Stability testing involves exposing pharmaceutical products to controlled environmental conditions and periodically analyzing them for changes in quality attributes. Key factors evaluated include:

Chemical Stability: Monitoring changes in the drug’s chemical composition or degradation products.

Physical Stability: Assessing changes in the product’s physical appearance, such as color, texture, and solubility.

Microbiological Stability: Ensuring that the product remains free from microbial contamination over time.

Therapeutic Efficacy: Confirming that the drug maintains its intended therapeutic effect throughout its shelf life.

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.