PPIC stands for “Production Planning and Inventory Control” in the context of the pharmaceutical industry. It refers to the systematic process of managing and optimizing production activities and inventory levels within a pharmaceutical manufacturing or distribution organization.

Table of Contents

Definition

To put it simply, it can be said that you need to work out how many raw materials and packaging items you have in stock and how much you need to buy to fulfill all stages of production planning according to the market demand of your company.

It is also a very important department among the many departments of pharmaceuticals. Nowadays, almost all companies deal with this department. This department is of immense importance for the company to meet the demand for its products in the market and to maintain quality.

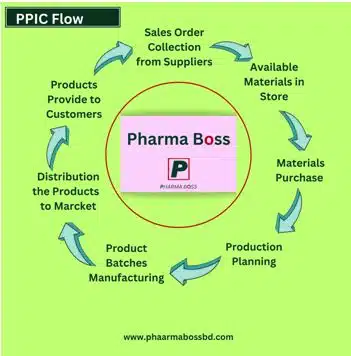

Various Steps of PPIC

If we look at the activities of this department, the following steps come into discussion:

1. Market demand for the product

The first step in any production process is to assess the market demand for the product. This involves conducting market research to understand customer preferences, identifying potential target demographics, and estimating the quantity of the product that consumers are likely to purchase. A clear understanding of market demand helps in determining production goals and sales forecasts.

2. Production planning

With market demand data in hand, production planning takes place. This phase involves deciding on the production volume, scheduling production runs, and establishing the production timeline. It also includes determining the necessary production resources, such as labor, machinery, and production facilities.

3. Stocked raw materials and packaging items

Before production can commence, it’s essential to ensure that all required raw materials and packaging items are in stock. This involves managing inventory levels to prevent shortages or overstocking. Raw materials should be inspected for quality and compliance with production standards.

4. Purchasing the remaining raw materials and packaging items required

In cases where not all the necessary raw materials and packaging items are already in stock, procurement becomes necessary. This step involves ordering and acquiring the remaining materials from suppliers. It’s crucial to maintain good relationships with suppliers to ensure timely and cost-effective procurement.

5. Production activities and

This stage involves the actual manufacturing of the product. It includes setting up the production line, performing quality control checks at various stages, assembling or processing raw materials, and monitoring production efficiency. Safety protocols and quality standards must be adhered to during this phase to produce a high-quality product efficiently.

6. Supplying the product to the market

After production, the final product is prepared for distribution to the market. This includes packaging, labeling, and sometimes storage, depending on the product type. Distribution channels such as wholesalers, retailers, or e-commerce platforms are utilized to reach consumers. Effective logistics and distribution management are crucial to ensuring timely and cost-effective product delivery to customers.

Each of these stages is essential for the successful production and supply of a product. Proper planning, management, and coordination are required throughout the entire process to meet market demand efficiently and effectively.

Parts of PPIC

We can analyze it in two parts. One is Production planning, and another is Inventory Control.

Production Planning:

Production planning involves determining what pharmaceutical products need to be produced, in what quantities, and by when. This process takes into consideration factors such as demand forecasts, available resources, production capacities, and lead times. The goal is to ensure that the right amount of pharmaceutical products is manufactured to meet customer demand while minimizing production bottlenecks and costs.

Inventory control

It deals with controlling the stock levels of pharmaceutical products. It includes striking a balance between the necessity to have adequate inventory on hand to quickly fill orders and the desire to avoid building up too much stock that takes up cash and storage space. Lead times, demand volatility, safety stock levels, and reorder points are all elements that effective inventory control takes into account.

The Aims of PPIC

PPIC in the pharmaceutical industry essentially attempts to achieve a balance between production and inventory management, ensuring that pharmaceutical companies efficiently meet client requests while containing costs and maintaining ideal inventory levels. This contributes to smoother operations, reduced wastage, and improved customer satisfaction within the pharmaceutical supply chain.

Roles of PPIC

Let’s discuss the specific roles of PPIC in the context of pharmaceuticals:

1. Demand Forecasting:

This step involves predicting the future demand for pharmaceutical products based on historical data, market trends, customer orders, and other relevant factors. Accurate demand forecasting helps in planning production quantities and scheduling to avoid stockouts or overstock situations.

2. Master Production Schedule (MPS):

The MPS is a detailed plan that specifies what pharmaceutical products to produce, in what quantities, and when. It takes into account the demand forecast, production capacity, lead times, and any other constraints. MPS serves as a foundation for production planning.

3. Material Requirements Planning (MRP):

MRP involves determining the raw materials, components, and other resources required to fulfill the MPS. It considers lead times, supplier availability, and existing inventory levels to ensure that the necessary materials are available when needed.

Read Also: GxP in The Pharmaceutical Industry

4. Production Scheduling:

Once the materials and resources are identified through MRP, production scheduling determines the sequence and timing of manufacturing operations. It aims to optimize machine and labor utilization, reduce changeover times, and minimize production bottlenecks.

5. Capacity Planning:

This step involves evaluating the production facility’s capacity to meet the production requirements outlined in the MPS. It considers factors like machine availability, labor shifts, and equipment maintenance to ensure a smooth production flow.

6. Inventory Control:

Maintaining appropriate inventory levels is essential to avoid stockouts and excessive carrying costs. PPIC aims to strike a balance between production and inventory, minimizing holding costs while ensuring products are available for timely delivery.

7. Order Release:

Based on the production schedule and available capacity, production orders are released to the shop floor. These orders provide instructions for producing specific quantities of pharmaceutical products.

8. Store House Floor Control:

Once production begins, store house floor control monitors and manages the actual production process. This involves tracking progress, addressing issues that may arise, ensuring quality control, and maintaining adherence to the production schedule.

9. Performance Monitoring and Adjustment:

PPIC involves continuous monitoring of production performance against the MPS and demand forecast. If discrepancies arise due to unforeseen events or changes in demand, adjustments can be made to the production plan and inventory levels.

10. Collaboration and Communication:

Effective communication and collaboration among various departments, such as production, procurement, sales, and logistics, are essential for a successful PPIC. Timely information sharing helps in addressing potential disruptions and ensuring a cohesive production process.

Conclusion

In conclusion, Production Planning and Inventory Control (PPIC) plays a vital role in the pharmaceutical industry by ensuring that production processes are well-coordinated, inventory levels are optimized, and products are manufactured in compliance with regulatory standards. Effective PPIC strategies contribute to the timely delivery of pharmaceutical products, cost savings, and overall operational excellence.

Frequently Asked Questions (FAQs)

What is PPIC in Pharma?

PPIC in Pharma (Production Planning & Inventory Control) refers to the strategic management of pharmaceutical manufacturing processes and stock levels. It involves optimizing production schedules, ensuring efficient resource allocation, and maintaining appropriate inventory levels to meet demand while minimizing costs and waste in the pharmaceutical industry.

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.

Hello sir,

i wants the questions asked in PPIC interview.

Can you Please share

Thank you sir. I will add questions about this.