Learn about (Standard Operating Procedure) SOP for operating of steam sterilizer in the Pharmaceutical Industry.

1. PURPOSE

To describe the operating procedure of the steam sterilizer.

2. SCOPE

This SOP shall be applicable to describe the operating procedure for the Autoclave located in the Quality Control department

3. ASSOCIATED DOCUMENTS

Nil

4. RESPONSIBILITIES

4.1 Senior Officer/Executive, Microbiology, is responsible for the operation of the steam sterilizer.

4.2 Senior Executive/ Executive, Microbiology is responsible for supervising the accuracy checking

work.

5. ACCOUNTABILITY

The head of the Quality Control Department shall be responsible.

6. PRECAUTIONS

6.1 Do not pour anything except for water.

6.2 Be careful not to pinch your hands when closing the lid.

6.3 After operations are finished, lift the lid while keeping your hands and face away from the chamber.

6.4 After the operation is over, the lid, chamber, packing and panel are hot, do not touch them with bare hands.

6.5 It takes a lot of time for the liquid to cool. Before removing the liquid from the chamber, make sure the temperature has lowered enough.

6.6 Put on heat insulation gloves before taking a substance out of the chamber. Do not enter the room with your hands inside until the steam has been released.

7. PROCEDURE

7.1 Place the substance to be sterilized into the chamber

7.2 While having the handles, lift up the lid cover

7.3 When closing the upper part of the stream sterilizer ensure that every opening point is closed tightly after loading all of the sterilization items then close the lid tightly and connect the power line.

7.4 After loading all of the sterilization items close the lid tightly and connect the power line.

7.5

| Mode | Application |

| 1 | Sterilization of agar medium (warned for the prevention of coagulation after sterilization. |

| 2 | Sterilization of tools made of glass, ceramic, metal, or rubber that withstands high temperature, high-pressure steam, and abrupt de-pressurization during the exhaust process. |

| 3 | Sterilization of tools of glass, ceramic, metal,, or rubber that withstand high temperature, high-pressure steam, and abrupt de-pressurization during the exhaust process. |

| 4 | Dissolution of Agar. |

7.5.1 On the top of the machine, there is a display bar where temperature and pressure is shown. For sterilization 121° C temperature in 15 minutes and 0.15 pressure to needed. When the machine is up to this remark then the power supply is cut off.

7.6 When the temperature showing below 40° C then open the lid carefully and take the sample.

Read Also: SOP for Batch Numbering System

8. ABBREVIATIONS

8.1 QA -Quality Assurance

8.2 QC -Quality Control

8.3 PD -Product Development

9. APPENDICES

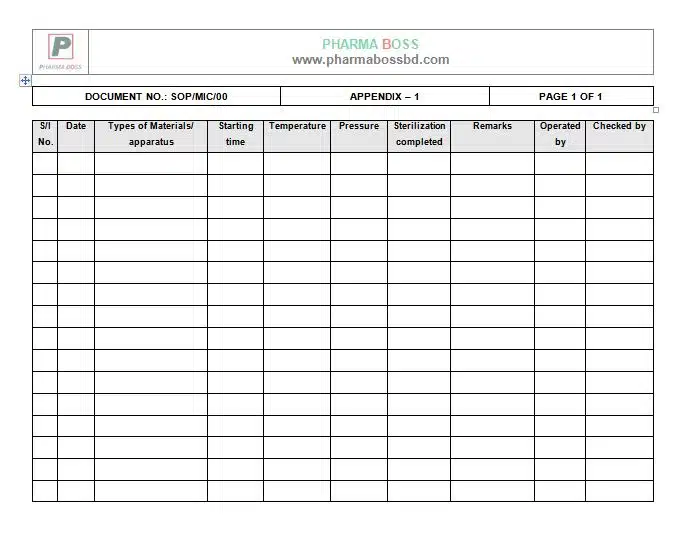

9.1 Appendix-1: LOG sheet for the Steam Sterilizer

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.