Learn how to write a procedure for cleaning of sampling tools used for sampling in pharmaceuticals.

1. PURPOSE

The purpose of this procedure is to establish a system for cleaning of sampling tools used for sampling.

2. SCOPE

This procedure is applicable for all sampling tools to be used for raw material sampling by Quality Control Department.

3. ASSOCIATED DOCUMENTS

Nil

4. PRECAUTIONS

4.1 Avoid used of any material corrosive to sampling tools.

4.2 Avoid use of any sharp object to rub or scrub out sticky materials.

4.3 Use non-shedding clean nylon brush, non-scratching to stainless steel tools.

4.4 Used non-shedding clean duster.

4.5 Use gloves, masks and overall

5. RESPONSIBILITIES

5.1 Lab Analyst is responsible for cleaning of sampling tools

5.3. Quality Control officer is responsible for checking the procedure.

6. ACCOUNTABILITY

Head of the Department

Read Also: SOP for Qualification of Working Standard

7. PROCEDURE

7.1 Collect all tools in a basket.

7.2 Tag the basket with “TO BE CLEANED” label.

7.3 Transfer the basket to the washing area.

7.4 Collect a nylon brush and a clean duster from storage area.

7.5 Take hot water in basin to emerge whole surface of tools.

7.6 Wait for 5 – 10 minutes.

7.7 Take them out of water.

7.8 Flush with running Nano pure water/purified water ensure free from sampled material

7.9 Mop them with dry and clean non-shedding duster to remove water from surface.

7.10 Keep all tools in the basket after drying with compressed air and with ethanol. Rap the tools with Aluminum foil or polyethylene.

7.11 Check them visually for cleaning and dying.

7.12 Tag the basket with ‘CLEANED’ label.

8. ABBREVIATIONS

8.1 SOP: Standard Operating Procedure

8.2 QC: Quality Control

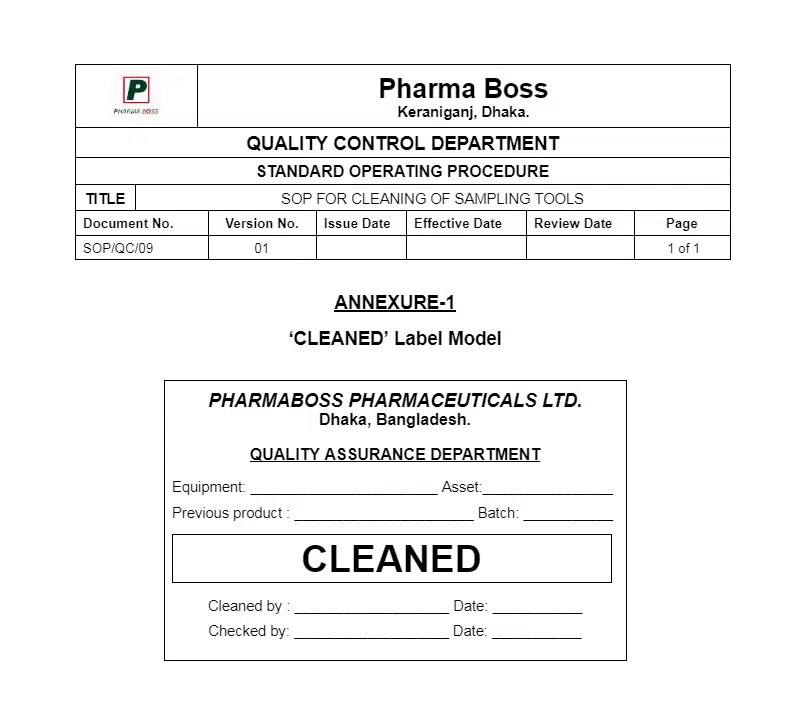

9. ANNEXURES

9.1 Annexure -1: ‘CLEANED’ Label Model

Annexure for cleaning of sampling tools

Abdus Sobhan Salim is professional experienced pharmacist in pharmaceuticals, author and founder of pharmabossbd.com, the first Bangladeshi pharmaceutical blogger since 2019.